Predictive Maintenance: Moving Beyond the Flawed Calendar-Based Approach

Most preventive maintenance programs still run on a simple clock: replace a filter every 90 days, inspect a motor quarterly, grease bearings once a month. While this method is easy to schedule, it’s inherently inefficient. You either service equipment that doesn’t need it or, worse, miss the early signs of a developing failure.

After two decades in maintenance and facilities management, I can tell you — calendar-based PM will cost you money, downtime, and credibility. The solution is predictive maintenance: servicing equipment based on its actual operating condition, not a date on a spreadsheet.

Where Calendar-Based PM Wastes Time and Money

Over-servicing components – I’ve seen air filters replaced with 70% of their life still in them simply because “it’s time.” That’s money wasted on labor and materials.

Underestimating risk – A bearing doesn’t care that it’s not due for service for another 30 days. If it’s running hot or vibrating abnormally today, you’re already behind.

Operational disruption – Pulling a system offline for “routine maintenance” when it’s not necessary hurts throughput, especially in 24/7 production environments.

Condition-Based Maintenance in Action

Predictive maintenance works by monitoring actual asset performance and acting only when the data indicates service is needed. Here’s how it looks in practice:

Air Handling Units (AHUs) & Dust Collection Systems

Install differential pressure sensors across air filters.

Set a threshold (e.g., +0.5" WC above baseline) to trigger a filter change.

This ensures changes happen only when airflow is restricted — not just because 90 days have passed.

Water Filtration Systems

Use inline pressure transmitters before and after filters.

Program alerts when delta pressure reaches your operational limit (e.g., +10 PSI).

In facilities with critical process water, add flow meters to confirm output capacity in real time.

Motors, Gearboxes, and Pumps

Deploy vibration sensors (measuring RMS velocity, acceleration, and high-frequency bearing data) to detect imbalance, misalignment, or bearing wear.

Pair with temperature sensors for thermal trending. A sustained +10°C above baseline can cut insulation life in half.

For critical assets, integrate these into a wireless gateway for remote monitoring and automated alerts.

Practical, Cost-Effective Technology

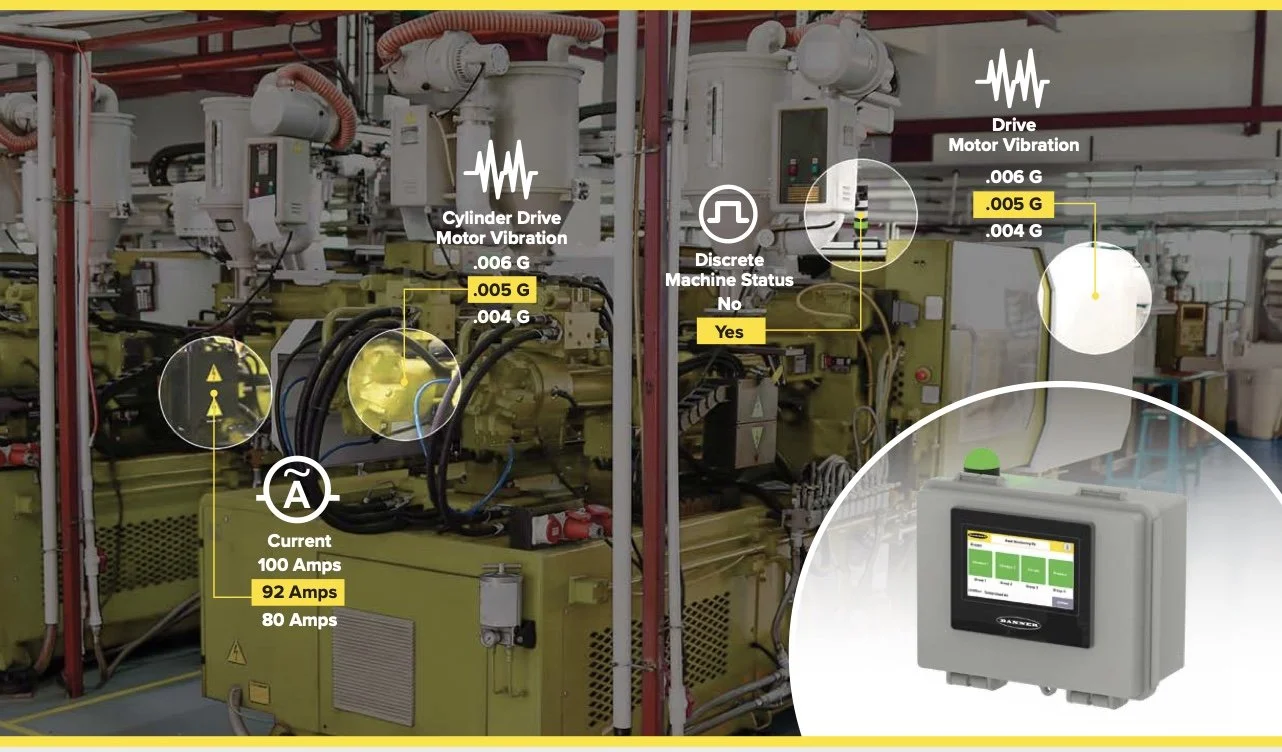

Not every facility needs a six-figure predictive maintenance system. Vendors like Banner Engineering offer scalable solutions that can be deployed incrementally:

Wireless nodes with temperature and vibration sensors mount directly to equipment — no hardwiring needed.

Gateways push data to a cloud dashboard or your existing CMMS.

Alerts can be sent via email, text, or even integrated with work order generation.

Example of various techniques (this is not a sponsored post by the way, just a system I’ve deployed)

Example: At one facility, I installed Banner wireless vibration sensors on three critical blower motors feeding our dust collection system. Within two months, the system flagged an abnormal increase in vibration velocity on one unit. We found and corrected a loose coupling before it failed — avoiding what would have been a full shift of lost production.

Why It’s Critical in Manufacturing

In manufacturing, downtime is measured in dollars per minute. Predictive maintenance:

Extends asset life – You’re not over-servicing or letting problems go unchecked.

Improves labor allocation – Technicians spend time where it’s needed most.

Reduces parts waste – You’re replacing components at the end of life, not halfway through it.

Protects uptime – Failures are caught before they impact production.

The Bottom Line

Calendar-based PM is easy — but it’s lazy maintenance. Predictive maintenance takes a bit more setup, but the payback is fast: less downtime, reduced costs, and higher reliability.

If your facility is ready to move beyond the calendar, I can help you design and implement a predictive maintenance program that’s right-sized for your operation and budget — from low-cost wireless sensors to fully integrated plantwide solutions.

📧 israel@ollieltd.com

🌐 www.ollieltd.com