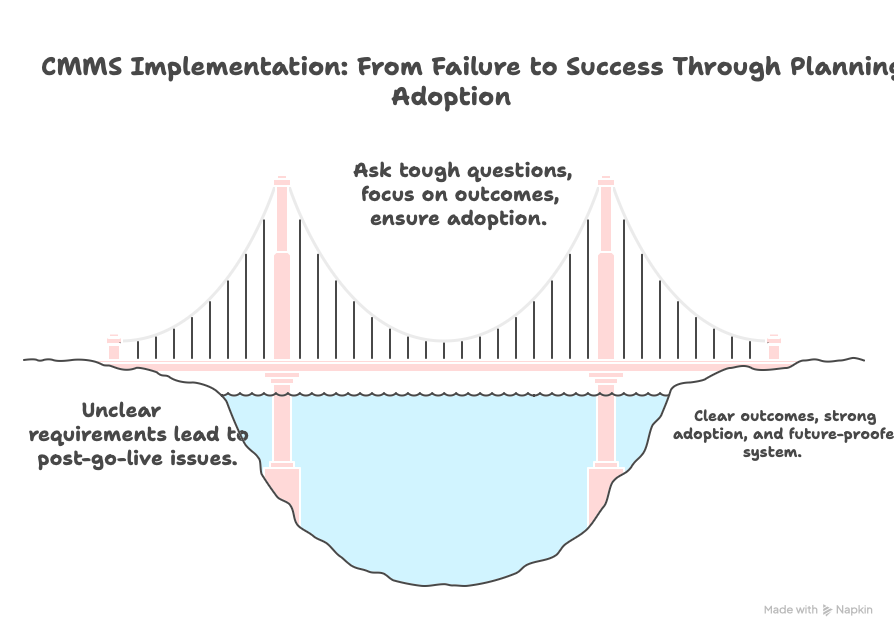

Why CMMS Implementations Fail - and How To Do Them Right

Most CMMS failures aren’t about the software itself. They’re about assumptions, unclear requirements, and the gap between what you see in a demo and what happens after go-live. I’ve implemented Maximo and Fiix, and I’ve worked with SAP PM, UpKeep, and others. Across all of them, the lesson is the same: if you don’t ask the right questions at the start, you’ll feel the limits later.

The reality after go-live

When we rolled out Fiix, the system looked perfect on paper. Custom workflows sounded like a game changer—until we discovered our plan only allowed for two of them. Integration with equipment and ERP systems was marketed as possible, but in practice it required heavy vendor involvement and serious resources. The mobile app struggled to update in real time. Exporting data for tools like Power BI turned out to be more complex than expected.

None of this means Fiix is a bad system—it’s powerful, evolving, and one I’d recommend to the right organization. But the key is going in with your eyes open. Vendors will show you the ideal scenario. The reality is you have to dig deeper, pressure-test their answers, and think not just about today’s needs but about where you want the system to be in three to five years.

Buy outcomes, not features

The best way to approach a CMMS implementation is to stop chasing feature lists and instead focus on outcomes. What do you need the system to deliver in the first 12 months? Reduced reactive work? Digital control of critical asset records? Full adoption by technicians? Once those outcomes are clear, you can evaluate features through that lens.

Then, think further out. What will your program need in three to five years? Condition monitoring? Automated parts reordering? ERP integration for costs and work orders? Long-term reliability dashboards? If you don’t plan ahead, you’ll lock yourself into a system that may not grow with you.

The right questions to ask

When you evaluate platforms, ask vendors to show you—not just tell you—how the system handles things like workflow limits, mobile performance, offline capability, integrations, data exports, and reporting. Push them to walk through live builds, not just slide decks. Bring in stakeholders from different areas: supervisors, storeroom staff, safety, finance, and IT. Each group has pain points that the system must address.

Implementation that sticks

Success doesn’t come from buying the right system—it comes from how you implement it. Keep it simple at first. Start with a few critical workflows, clean your data before migrating, and train people by role using real examples from your operation. Pilot in one area before rolling out across the plant. Measure adoption, fix friction points quickly, and then add advanced features over time.

What matters most is that technicians actually use the system. Track things like logins, PM completion, work order details, photo attachments, and cycle times. If the numbers aren’t moving, it’s not an adoption problem—it’s a workflow problem.

Integration and future-proofing

Integration with ERP, finance, or analytics platforms is where the real investment comes in. Treat it like a capital project. Define which system owns which data, decide on sync frequency, and budget both money and time for testing. Make sure you understand how to extract your data if you ever transition to another platform.

The bottom line

A CMMS can absolutely transform maintenance and facilities management—but only if it’s implemented with clear outcomes, tough questions, and strong adoption practices. If you’re exploring a new system, or if your current one isn’t delivering, I can help.

I provide fractional facilities leadership, TPM and maintenance program audits, SOP development for safety and contractor management, CMMS setup and optimization, OSHA compliance support, and capital project assistance from utilities review through commissioning. Remote support is available anywhere, and on-site support is available in the Denver metro area.